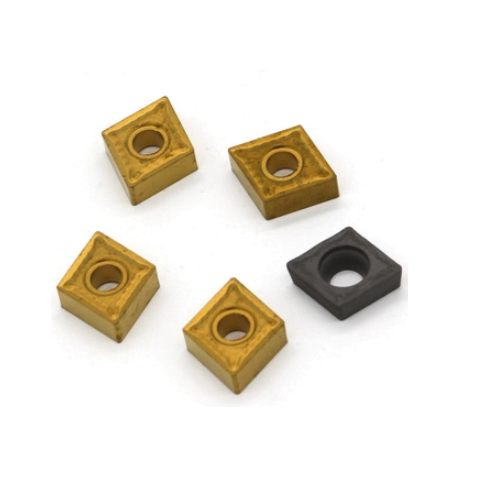

Inserts

Cutting tool inserts are commonly constructed of carbide, micrograin carbide, CBN, ceramic, cermet, cobalt, diamond PCD, high-speed steel, and silicon nitride.

Coatings help to increase wear resistance and insert life. Coatings for cutting tool inserts include titanium nitride, titanium carbonitride, titanium aluminum nitride, aluminum titanium nitride, aluminum oxide, chromium nitride, zirconium nitride, and diamond DLC.

A diamond insert is a four-sided insert with two acute angles used for material removal. Square cutting tips have four equal sides.

Rectangular inserts have four sides, two of which are longer than the other two. These inserts are often used for grooving, where the short sides contain the actual cutting edge.

Rhombic or parallelogram inserts are four-sided, with an angle on the sides for cutting point clearance.

- Cutting tool inserts can have many different geometries..

- Round or circular inserts are used in applications such as button mills or in radius groove turning. Some types are adjustable to employ unused edge portions once part of the edge is worn.

- Triangle inserts have a triangular shape; three equal sides and three tips with included angles of 60 degrees.

- These inserts are often used for grooving, where the short sides contain the actual cutting edge.

Address

Plot No.110,Por Industrial Park,

B.H.Sahyog Hotel,N.H.8,Por,

Vadodara:-391243

Contact

Mo.9879580073